New thermoelectric material may reduce wasted energy

Author: Amy Juhnke

Author: Amy Juhnke

Waste energy in the form of heat has big potential that Kirill Kovnir wants to see recaptured and used.

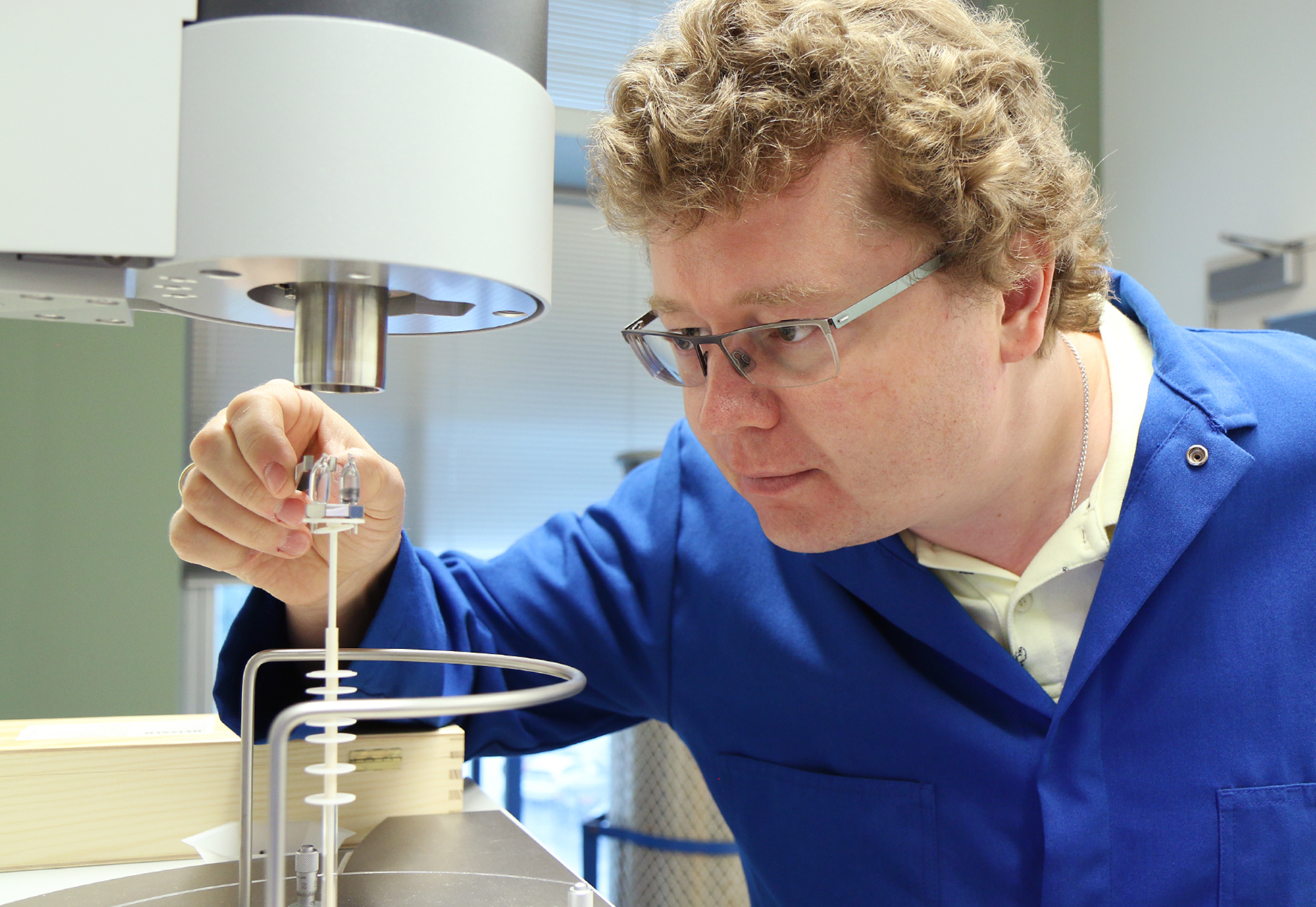

Kovnir, associate at the U.S. Department of Energy’s (DOE) Ames Laboratory and associate professor of chemistry, searches for new thermoelectric materials that can be used to harness heat energy into electricity. These materials are often used in space as well as capturing lost heat energy on earth.

“Normally as a country in general, we waste more than 60 percent of the energy we generate as heat, which we emit to the environment,” Kovnir said.

A common example is the heat lost from typical car engines. If the high temperature of the exhaust gas could be recaptured and converted back into electrical energy through the use of thermoelectric materials, the overall fuel efficiency of the car would greatly increase.

The new material he synthesized is an intermetallic clathrate, a solid compound in which one component is trapped within the crystalline framework of another. Clathrates had been predicted to have interesting and useful thermoelectric properties for some time, but synthesizing them has proven difficult due to the difficulty of matching the cage size with the element inside of it. Kovnir has synthesized a material made of copper-phosphorous cages each containing lanthanum cations.

This material serves as a good thermoelectric material due to maintaining a high electrical conductivity while having a low thermal conductivity, two elements necessary for thermoelectrics.

“We need a very good electrical conductor, but very bad heat conductor and these two properties are typically incompatible in one material,” Kovnir said.

The clathrate he synthesized is a metal, which gives it a high electrical conductivity. The lanthanum cation trapped inside the copper-phosphorous cage structure caused the intermetallic compound to have a low thermal conductivity.

“This atom trapped inside the cage will rattle,” Kovnir said. “When it rattles, that’s what actually allows this material to have this low thermal conductivity because the vibrations of that atom will dissipate heat.”

If the cage is not sized correctly this rattling phenomenon will not happen as there will be either not enough room for it to move, or so much room that the compound will become unstable.

Previous research had focused on using silicon cages, but the cage was often too large for a lanthanum rattler and with a single exception clathrate compounds did not form. Kovnir and his colleagues reduced the size of the cage by using a copper-phosphorous cage and also were able to use a smaller cation that produced the rattling effect within the cage, giving this new material promise for thermoelectric applications.

Read the published research [online.](https://www.cell.com/chem/fulltext/S2451-9294(18)30137-2)